High-volume syringe pump

-

skills: electromechanical assembly design • GD&T • feedback control • data acquisition • data analysis • structure design • measurement (e.g., position, volume, pressure)

hardware: 3D printers (SLA, FDM) • laser cutter • shop tools

software: MATLAB • SolidWorks • Arduino • KeyShot

-

Soft robots and actuators are typically made of elastomers—i.e., soft, stretchy plastics. For example, a rubber balloon can be used as a soft actuator to power locomotion in a soft robot. When you inflate a balloon, it has a characteristic pressure-volume curve. This curve gives you information about how the balloon deforms with pressure, but also how much work it takes to deform it. This information is particularly useful for the design of efficient soft actuators—an endeavor that sparked the need for this tool.

Off-the-shelf high-volume syringe pumps are commercially available. While these deliver high precision control over fluid dispensed (see New Era Systems) they are expensive, use buggy software, are challenging to program, and challenging to communicate with and get time data from… so I decided to build my own! 😅

-

The aim was to design, construct, and control a high-volume (i.e., ~360 mL) syringe pump capable of measuring pressures with <0.01 psi accuracy, and dispensing fluid with <0.5 mL accuracy. Here’s how I did that, broken down by section.

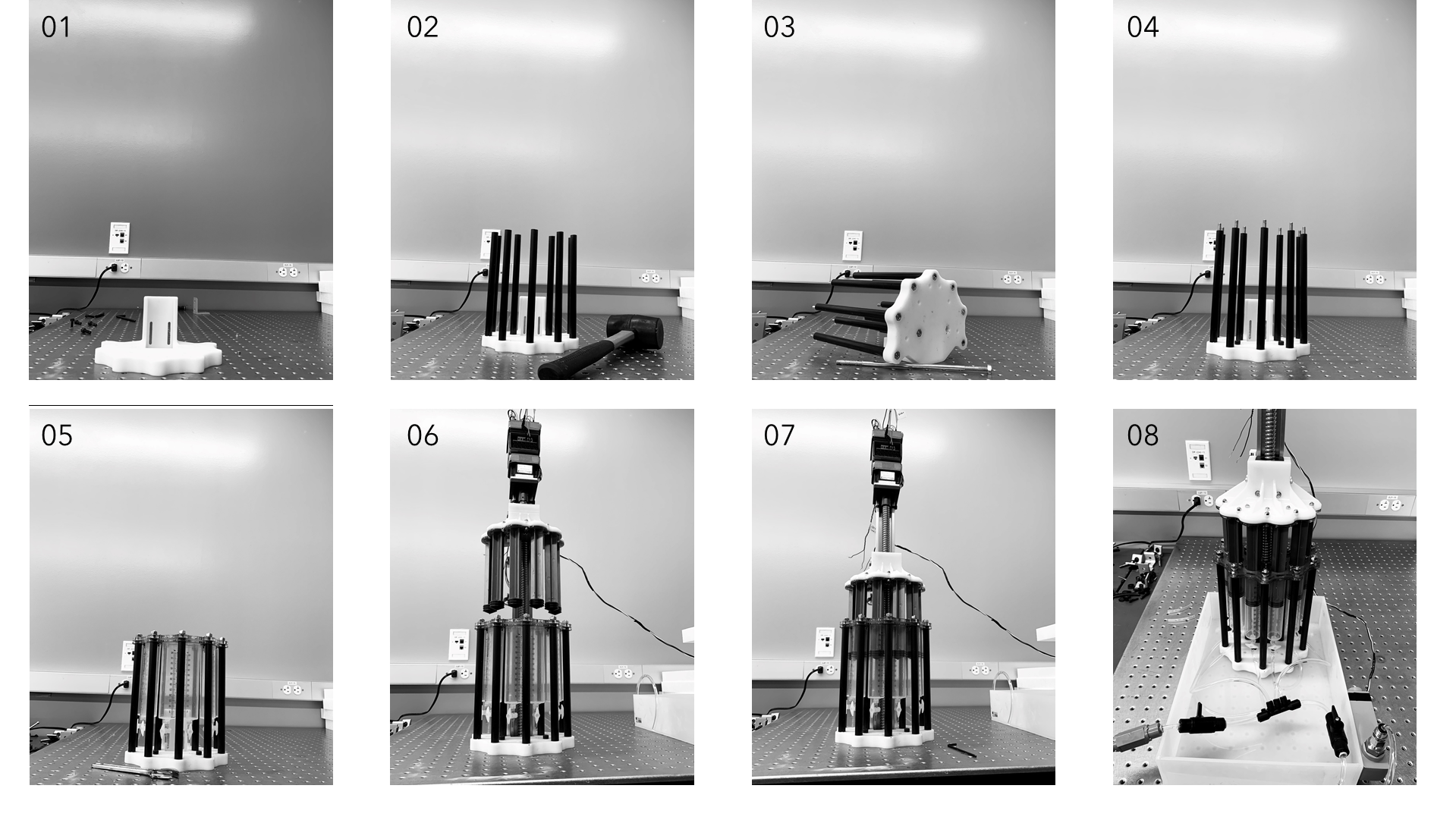

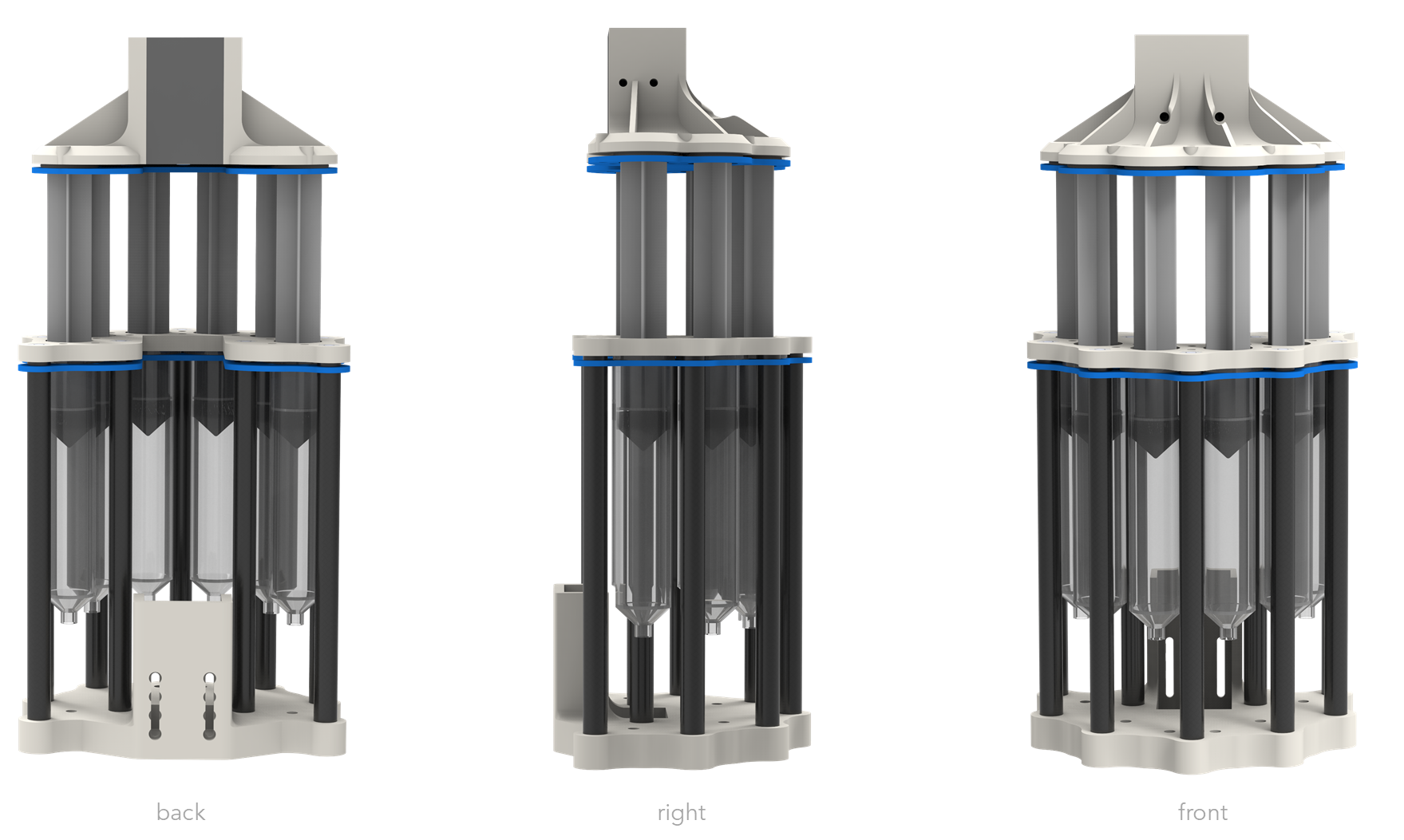

Structure. This syringe pump is comprised of stationary components that hold the syringes (and fluid), and moving components that translate plungers up and down to dispense/withdraw fluid (see labeled schematic above). The stationary structure that holds the syringes has to be stiff because any compliance results in inaccuracies in volume dispensed/withdrawn. To create a stiff frame without CNC machining (saving time, lowering complexity), I basically tensioned carbon fiber tubes between two stiff plates: a laser cut acrylic frame on the top and a 3D printed polypropylene base on the bottom. The acrylic frame held six 60 mL syringes, which totaled to a dispensing volume of 360 mL.

Control. A separate 3D printed polypropylene structure that held the six syringe plungers (see labeled schematic above) was then bolted to a linear rail that could be actuated by a stepper motor coupled to a ball screw (again, see schematic). I controlled this stepper motor using a TB6560 stepper motor driver and an Arduino Uno. All code was written in Arduino's IDE.

Data acquisition. Data acquisition was performed in series with the control code--which is actually not a great way to do things, but is also the only way to do things when using serial communication--using the Arduino Uno. The data I was curious about was pressure & volume.

For pressure data collection, I used a Dwyer 626 series pressure transducer, which supplies an analog signal that is digitized by your data acquisition system of choice. Using an Arduino Uno, the on-board analog-to-digital converter (ADC) only has 10 bits of resolution, meaning I could already get down to (30-0)[psi]/(2^10)[bits] ~ 0.030 psi. Operating at low (<2 psi) pressures, however, I used a 16-bit off-board ADC to achieve (30-0)[psi]/(2^16)[bits] ~ 0.00046 psi resolution (or 64x the resolution). The result was what I was looking for, with the accuracy being a fixed 0.25% full-scale accuracy inherent specified by the pressure transducer manufacturer.

Volume data was calculated by converting the number of steps taken (known via code) to some linear distance traveled by the plungers to some volume dispensed. Unfortunately, my stepper motor lacked an encoder and thus the system lacked rotational position feedback. To remedy this, I hacked a pair of digital calipers and fixed them both to the stationary and moving parts of the apparatus to measure linear displacement.

However, despite my best efforts, there was a lot of hysteresis (i.e., programmed volume dispensed ≠ actual volume dispensed) in the system due to a combination of flexing materials (i.e., the laser cut plastic parts), deformability of the rubber plunger tips, and probably compressibility of small air pockets in the plumbing.

The outcome? I ultimately abandoned this custom setup for an off-the-shelf apparatus with +/- 0.6 mL accuracy for simplicity and peace of mind. While I hate "quitting," this endeavor was a valuable exercise in know when to quit and why. In this case: because an off-the-shelf solution was superior than my own. Nonetheless, the engineering lessons learned & confidence gained in my design, control, and data acquisition skills are invaluable and carried me through two more projects that required similar skillsets.