Engineer

Hi, I’m Luke. I’m an

&

Researcher

a jack of all trades, master of some.

Luke is a force to be reckoned with. He combines technical mastery and research skills with work ethic and an ability to teach himself whatever he has to. This combination makes him able to tackle any problem. Something else that always struck me about Luke is how he will never say something is impossible, even if the odds are stacked against him. He will give it his 100%, and often ends up proving everyone else wrong. And after he's succeeded, he is exceptional at sharing his work—he is one of the best presenters I've worked with.

-Elliot Hawkes (PhD Adviser), LinkedIn Recommendation

[I promise you I didn’t pay him to say this. To be honest, as a graduate student, I don’t think I could have afforded to.]

EDUCATION & TRAINING

I built my engineering foundation in college—pursuing a B.S. in mechanical engineering at Penn State alongside extracurriculars such as formula racing (FSAE).

I became more “T-shaped” by persisting through a PhD in mechanical engineering at UC Santa Barbara. I gained deep expertise in problem-solving, experiment design, project management, critical thinking, leadership, and countless technical skills. I also mastered my ability to communicate technical information to the layperson.

SELECT SKILLS

Software: MATLAB · CAD (Solidworks, Fusion 360) · Arduino / C++ · COMSOL Multiphysics · Solidworks Flow Simulation

Research: experiment design · sensor selection · data collection & analysis · automated data processing · mechanical testing · imaging · electromechanical test assemblies · cross-disciplinary collaboration

Prototyping: 3D printing · laser cutting · machining (lathe, end-mill, GD&T) · molding/casting

Interpersonal: collectivist attitude · consensus building · critical thinking · leadership · empathy

SELECT WORK EXPERIENCE

Researcher, Accenture Labs (Oct 2022 - pres.)

Defined group research agenda focused around advanced manufacturing research and techniques

Learned and leveraged laser techniques for producing graphene-rich traces on thin flexible substrates (LIG). Prototyped heaters, supercapacitors, pressure sensors, flex sensors, from this approach.

Leading a patent on an ultrathin wearable physiological sensor

Researcher, Hawkes & Valentine Labs (Sep 2017 - May 2022)

Thermodynamics & Mechanism Design. Applied thermodynamic theory to improve the efficiency of soft bellows-like actuators; designed and built a test apparatus to validate theoretical findings; designed and built a soft robot capable of locomotion using only sunlight and no electronics (in preparation).

Imaging & Image Analysis. Characterized the photokinetics of novel light-responsive opacity-switching dyes; leveraging these findings to create light-actuated muscles (published, Nature Communications, DOI: 10.1038/s41467-020-16277-7).

Structure Design, FEA, & Materials Testing. Characterized mechanical properties of novel multimaterial 3D prints (published, Material Horizons, DOI: 10.1039/D0MH00331J). Designed & characterized mussel-inspired adhesive structures (published, Journal of Applied Mechanics, DOI: 10.1115/1.4049392).

Mechanical Systems Analyst, KCF Technologies (Apr 2017 - Aug 2017)

Applied computational fluid dynamics (CFD) to diagnose cavitation issues in fracking components

Designed an improved manifold to minimize cavitation and increase fluid flow, verified by simulation

Cost savings of >$20M for customer in annual capital expenditures

SELECTED WORKS

✺

SELECTED WORKS ✺

Selected? Yes.

The subset of projects below are projects that have pretty pictures of physical things that have been built (mostly, if not only) by me. They showcase work in both industry and academia that leverage skills such as structural design, finite element analysis (FEA), fluid dynamics (CFD), and electromechanical assembly design.

Things that aren’t here? Less polished projects, projects that didn’t result in a tangible thing (e.g., code), and research publications (see my Google Scholar page).

Scroll on to the pretty pictures below. Enjoy!

2022 | Design & Fabrication of a Soft Solar-powered Robot

-

In graduate school, collaborators and I developed and proved some theory that illuminated the guiding principles for efficient soft heat engine design. To demonstrate what’s possible when leveraging efficient principles, I designed and built a soft robot that actuates with sunlight and no electronics.

-

hardware: 3D printer (FDM) • laser cutter • general shop tools

software: SolidWorks -

open loop feedback control • compliant mechanism design • structure design • optics design • thermodynamic analysis • extreme perseverance & patience 😮💨

2021 | Improving the Efficiency of Soft Steam Engines for Robotics

-

Heat is one of the simplest ways to drive actuation in soft-bodied robots… but how do you measure efficiency? This apparatus answers that question—focusing specifically on measuring the efficiency of a thermally-activated phase change actuator.

-

hardware: 3D printers (SLA, FDM) • laser cutter • various electronics & sensors

software: MATLAB • Arduino • COMSOL • SolidWorks -

electromechanical assembly design • simple feedback control • data acquisition • data analysis • structure design • 2D thermo analysis • precise measurement (e.g., temperature, motion, force, power)

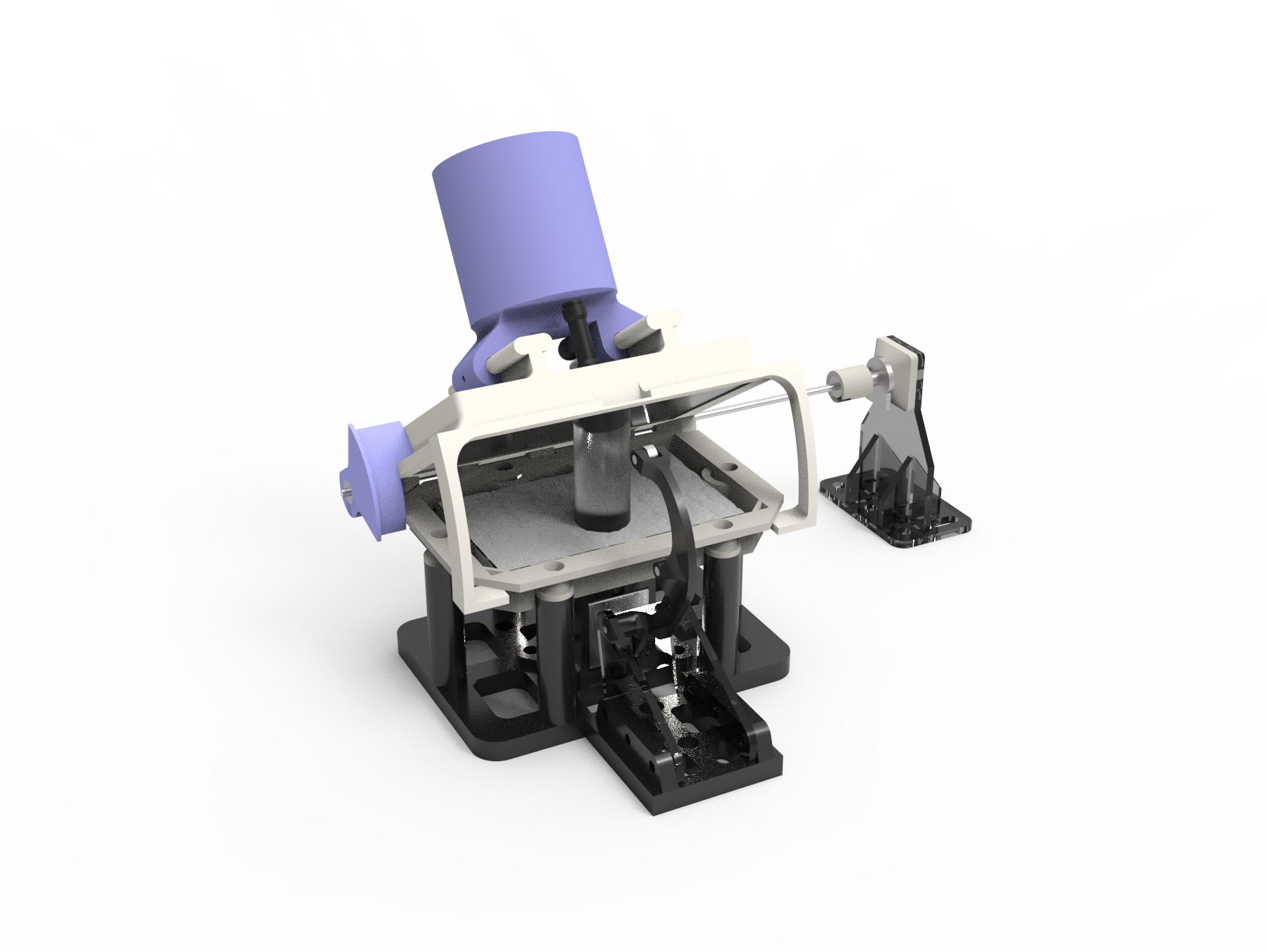

2021 | Improving the Efficiency of Soft Air Motors for Robotics

-

Heat is one of the simplest ways to drive actuation in soft-bodied robots… but how do you measure efficiency? This apparatus answers that question—measuring the efficiency of a thermally-activated air-based actuators.

-

hardware: 3D printers (SLA, FDM) • laser cutter

software: MATLAB • Arduino • COMSOL • SolidWorks -

electromechanical assembly design • simple feedback control • data acquisition • data analysis • structure design • 2D thermo analysis • precise measurement (e.g., temperature, motion, force, power) • delivering on tight deadlines

2020 | High-volume Syringe Pump

-

Most soft robots do work by leveraging pressure differentials inside of a soft, elastic body. The thing is, some work is also required to deform the soft elastic body (in addition to the work required to act on external bodies). To characterize how much work is required to deform a soft robot body, I built a custom syringe pump that enabled precise control of volume and analysis of pressures.

-

hardware: 3D printers (SLA, FDM) • laser cutter

software: MATLAB • Arduino • SolidWorks -

electromechanical assembly design • stepper motor control • data acquisition • data analysis • structure design • sensor design (i.e., pressure, linear actuation)

2017 | Oil & Gas Manifold Design Improvement

-

Working for a small startup in college, I designed a new type of manifold to remediate cavitation issues an oil & gas customer was having. The implementation of my design is still saving that customer unfathomable amounts of money per year.

-

software: SolidWorks • SolidWorks Flow Simulation

hardware: n/a - the client fabricated the design

-

fluid dynamics principles • computational fluid dynamics • data analysis • technical communication • design for manufacture • cost reduction

2017 | Removing Salt from Seawater Using Nanoparticles

-

In college, two optimistic (and maybe naïve) teammates and I endeavored to create an effective, low-cost, low-power method for producing potable water from seawater.

-

hardware: CNC mill • 3D printer (FDM)

software: Solidworks • MasterCam

-

nanoparticle synthesis • Raman spectroscopy • rapid prototyping • technical communication • leadership & teamwork

2015 | Cooling System for a Formula Racecar

-

Eager for some leadership experience in college, I led the design of a cooling system for Penn State’s formula racing team. The system had to keep a 600cc motorcycle engine cool on a hot day in Michigan in both aggressive racing and endurance driving conditions.

-

hardware: lathes • end mills • sanders • drills • general shop equipment

software: Solidworks • Excel

-

leadership • thermodynamics • molding & casting • composite fabrication • thermodynamics • rapid prototyping • teamwork

2011 | Design & Fabrication of a Hobbyist Motorcycle

-

A scary fun way to get around the neighborhood, disguised as a capstone design project. My first real foray into engineering and a defining moment in choosing what to study in college.

-

hardware: stick welder • pencil • paper

software: n/a

-

ergonomic design • fabrication in a resource-constrained setting • structure design • welding • technical communication